Navigating Nickel (Ni)

Scientific Properties of Nickel

Nickel is a transition metal with the chemical symbol Ni and atomic number 28. It has an atomic mass of 58.69 u and is part of the d-block elements on the periodic table. Nickel is known for its silver-white, lustrous appearance, high melting point of 1,455°C (2,651°F), and boiling point of 2,913°C (5,275°F). It has a density of 8.90 grams per cubic centimetre and exhibits excellent thermal and electrical conductivity. Nickel is both ductile and malleable, allowing it to be formed into wires and sheets. It is also ferromagnetic, meaning it can be magnetised, and it is resistant to corrosion and oxidation, particularly when alloyed with other metals.

Uses and Future Applications

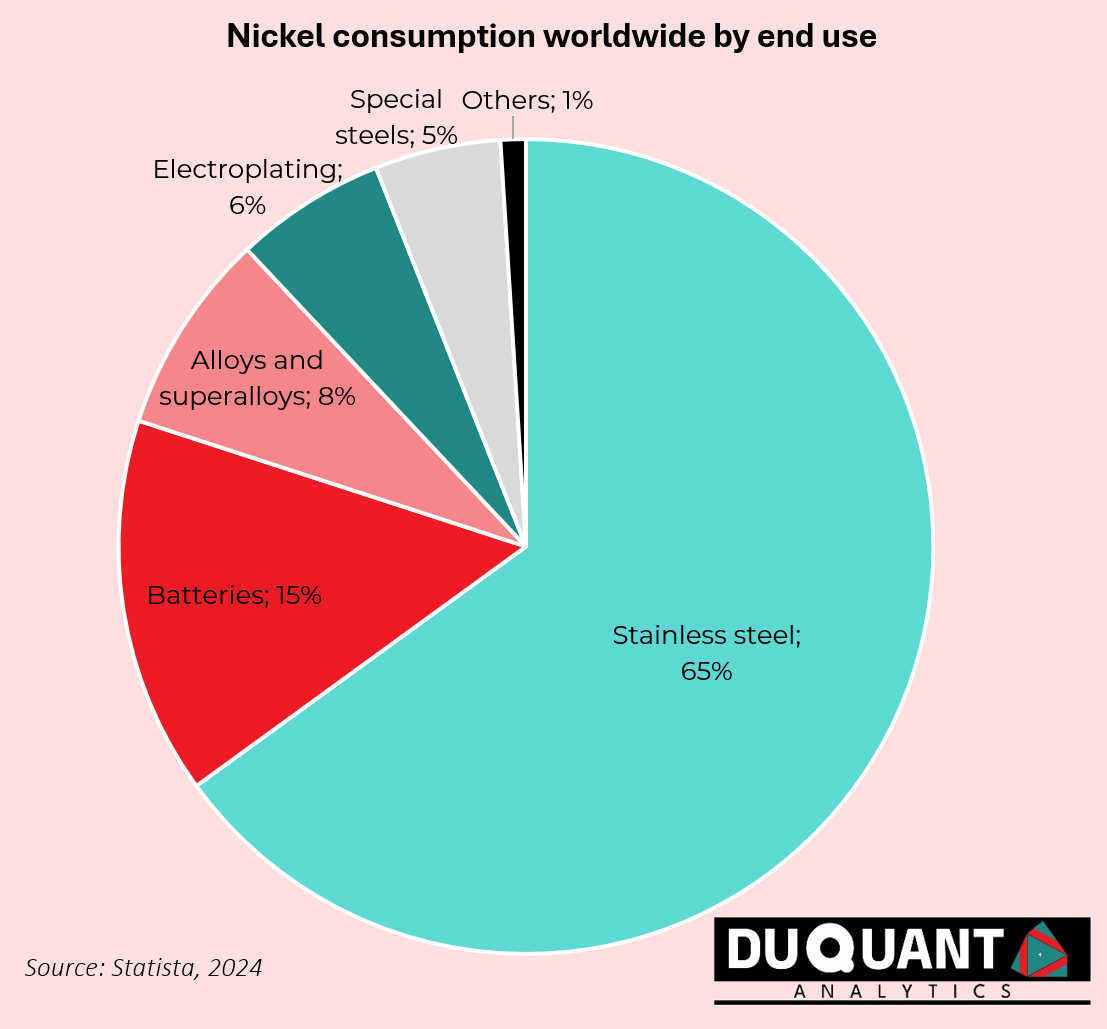

Nickel exists almost everywhere you look in modern society where nickel’s primary use is in the production of stainless steel. It enhances the metal’s corrosion resistance, strength, and ductility. Thus, almost all public infrastructure, buildings, transportation, and products that contain stainless steel, also contain nickel. Approximately c.65% of the world’s nickel production is used for this purpose in stainless steel.

With nickel’s ability to withstand high temperatures, this also makes it a critical component of high-quality steel and superalloys used in applications such as jet engines and aerospace. Nickel is also crucial in the manufacture of superalloys, which are used in aerospace, power generation, and military applications due to their ability to withstand extreme temperatures and mechanical stress. Additionally, nickel is used in the production of rechargeable batteries, particularly lithium-ion batteries for electric vehicles (EVs), which account for about c.15% of global nickel consumption. The future demand for nickel is expected to be driven by the rapid growth of the EV market, advancements in battery technology, and the continued expansion of infrastructure and industrial applications requiring stainless steel and superalloys.

Nickel’s future is bright with tailwinds for growth coming from an energy transition and further development of infrastructure in emerging markets. These trends are likely to benefit investors and the few countries that mine it around the world

Largest Sources and Producers of Nickel

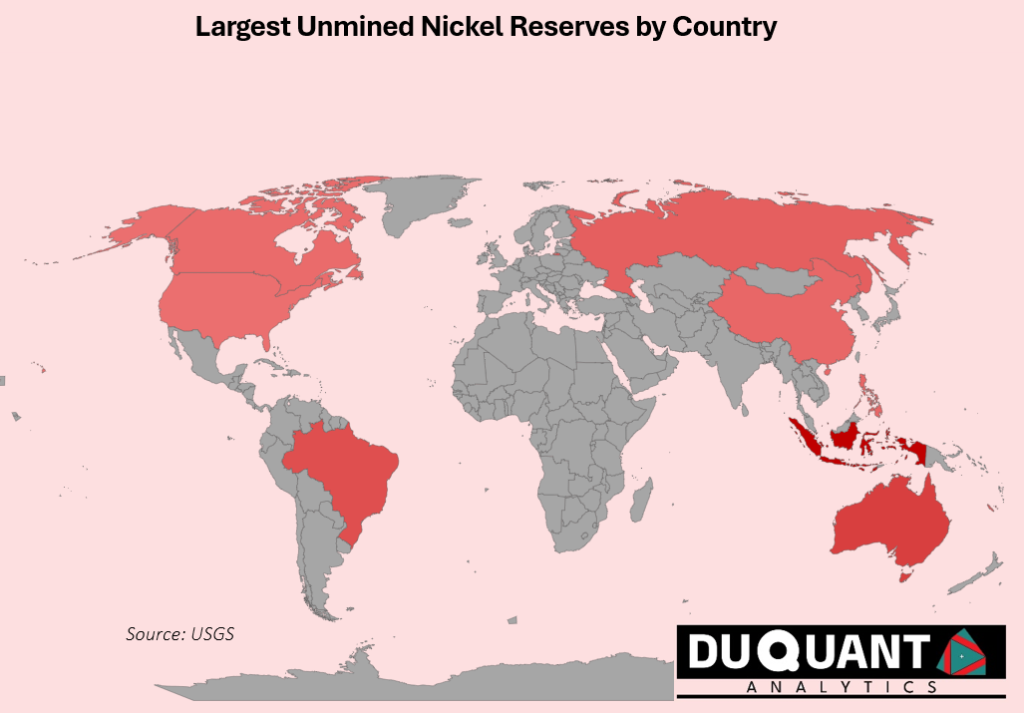

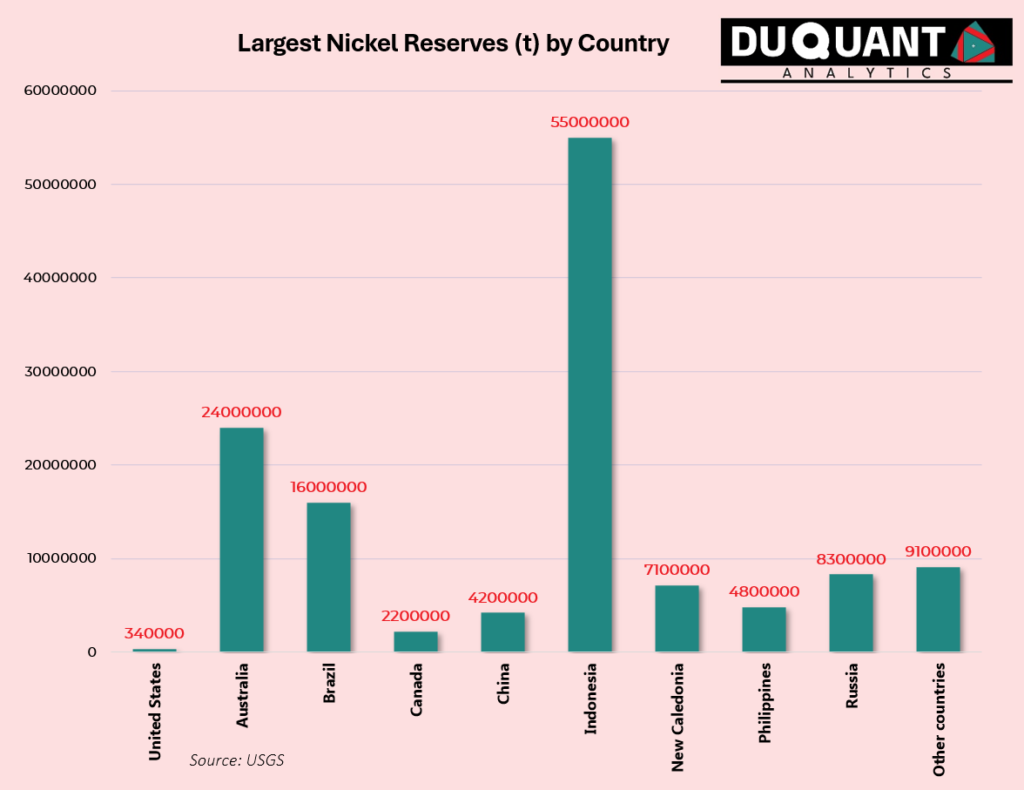

Nickel forms in nickel sulphide deposits with well known regions such as the Sudbury Basin in Canada, the Norilsk-Talnajh deposit in Russia and the Jinchuan Group found in China. The largest of all deposits, however, occurs in Indonesia and is a nickel laterite deposit, formed by the weathering of ultramafic rocks. A massive 43% of known nickel reserves are based in Indonesia.

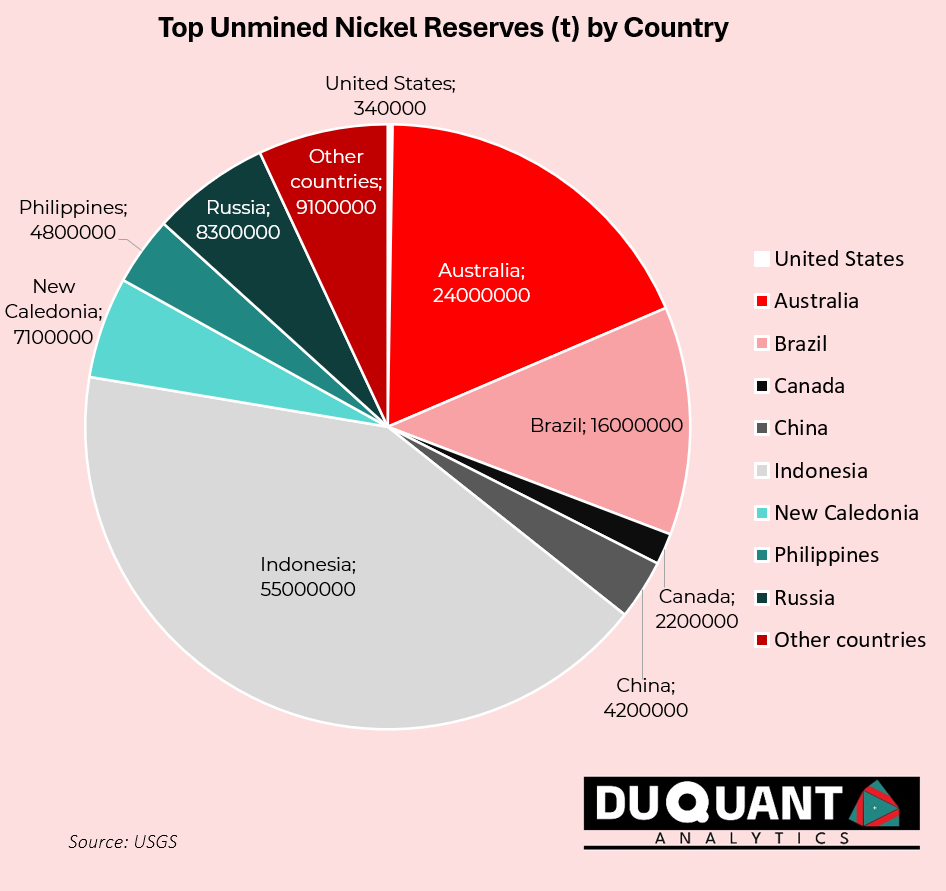

Nickel is found in many places around the world and according to the 2024 US Geological Survey (USGS), global Nickel reserves stand at 130,000 Kilo tons (Kt or 1000t) with the largest reserves being Indonesia (55,000 Kt), Australia (24,000 Kt), Brazil (16,000 Kt) New Caledonia (7,100 Kt). The remainder of the world makes up only 28,940Kt (or 22%).

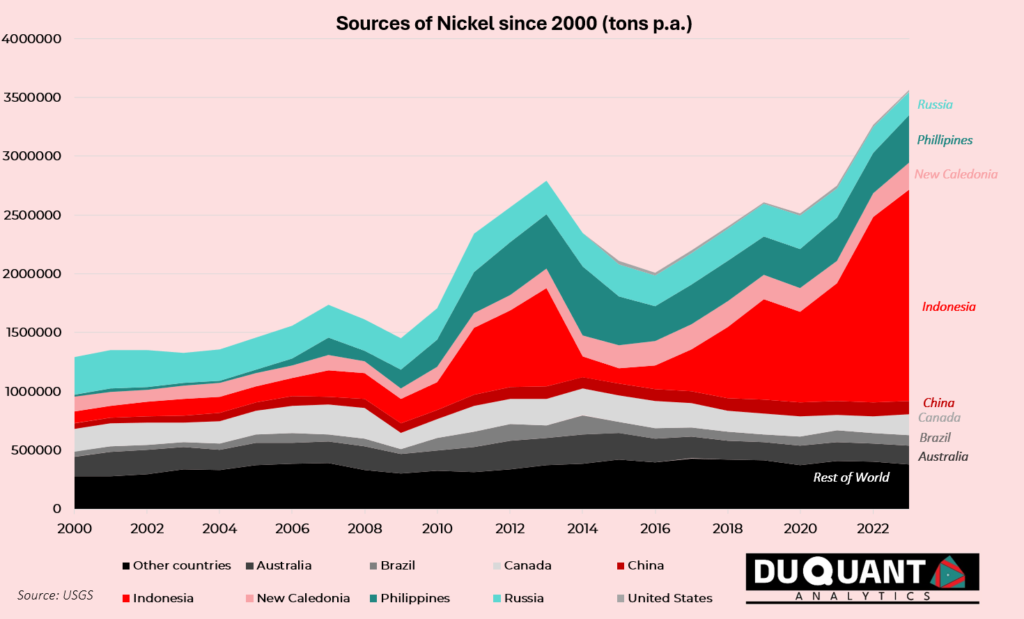

Nickel mine production from 2017 to 2023 has increased at a CAGR of 8.6% to an annual supply of 3,600,000 tons in 2023. The majority of this increase can be attributed to Indonesia, which experienced a 31% CAGR from 2017 to 2023. In terms of total annual mine production, since 2000 approximately 23% of Nickel came from Indonesia, followed by Russia (13%), Philippines (12%), Australia (9%), Canada (9%), New Caledonia (7%), Brazil (4%) and China (4%). The rest of the world has made up c.18% of the total mined supply of nickel since year 2000.

Based on the current annual production rate, and the estimated global reserves, there is c.36 years remaining of Nickel supply and thus a big drive to increase global investment and recycling initiatives. Nickels use is non corrosive stainless steel is vital for the production of infrastructure, EV’s equipment and will thus be a key focus going forward.

The Remarkable History of Nickel

Nickel, a versatile metal pivotal to modern industry and technology, boasts a rich history intertwined with human progress. Its evolution from a little-known mineral to an indispensable element in global industries is a compelling narrative of exploration, scientific breakthroughs, and industrial innovation.

Nickel’s history traces back to ancient times, where it was often mistaken for other metals due to its similar appearance. Early uses of nickel likely included the production of decorative items, but its distinct properties were not fully recognized until much later. During the medieval period, nickel was occasionally encountered in ores alongside copper, contributing unintentionally to the properties of various copper-based alloys.

Nickel’s true identity was only scientifically established in the 18th century. Swedish chemist Axel Fredrik Cronstedt is credited with isolating nickel as a new element in 1751. This discovery marked a turning point in understanding nickel’s unique properties and potential industrial applications. By the 19th century, advancements in metallurgy revealed nickel’s alloying capabilities, particularly its ability to strengthen iron and steel. This knowledge sparked increased interest in nickel mining and refining, laying the groundwork for its industrial use in the years to come. The early 20th century saw nickel’s role in metallurgy solidify, particularly in the production of stainless steel. The discovery that nickel could enhance the corrosion resistance and durability of steel revolutionized industrial manufacturing. Major nickel deposits were discovered and developed across continents, including Canada, Russia, and Australia, establishing these regions as key players in global nickel production.

Nickel played a crucial role in both World War I and II, where its properties were instrumental in producing high-strength alloys for military applications. Nickel-based alloys were used in aircraft engines, naval vessels, and other wartime technologies, underscoring its strategic importance and driving further advancements in mining and refining technologies. During the mid-20th century, nickel’s applications expanded beyond steelmaking. It became integral to the production of nickel-cadmium batteries, which were widely used in portable electronics and early electric vehicles. Additionally, nickel’s alloys found applications in aerospace, chemical processing, and electronics industries, further diversifying its industrial footprint.

Technological advancements in metallurgy and mining continued to drive nickel production into the late 20th century. The development of high-performance nickel-based alloys and the expansion of nickel refining capabilities contributed to its increasing demand across various industrial sectors worldwide. Significant nickel deposits continued to be discovered and developed globally, with regions like Indonesia, the Philippines, and New Caledonia emerging as major nickel-producing countries. These discoveries bolstered global nickel supply and contributed to the metal’s role as a critical component in modern industrial economies. The early 21st century has seen ongoing advancements in nickel mining technologies and sustainable practices. Efforts to improve environmental stewardship and ethical mining practices have gained prominence, reflecting a broader commitment to responsible resource extraction. As the global awareness of environmental impacts grows, the nickel mining industry faces challenges related to sustainability and responsible resource management. Efforts to mitigate environmental impacts, reduce carbon footprints, and enhance community engagement are shaping the future of nickel mining practices worldwide.

Looking ahead, nickel’s versatility and critical role in emerging technologies such as electric vehicles and renewable energy storage position it as a cornerstone of sustainable industrial development. Ongoing research and innovation aim to enhance nickel’s efficiency, recyclability, and environmental performance, ensuring its continued relevance in a rapidly evolving global economy. From its humble beginnings to its pivotal role in modern industry, nickel’s journey underscores its enduring significance and potential to drive innovation in the decades to come.

Navigating Nickel

Navigating Nickel High grade stainless steel would have less strength, durability and corrosion resistance if…